Waterborne Adhesives play an essential role in automotive manufacturing, where strong, reliable, and environmentally friendly bonding solutions are critical. These adhesives are used throughout the production of automobiles, from assembly to finishing, providing effective solutions for bonding various materials, including metals, plastics, glass, and textiles.

One of the key benefits of Waterborne Adhesives in the automotive industry is their environmental safety. Traditional adhesives often contain solvents that release harmful volatile organic compounds (VOCs) into the atmosphere, contributing to air pollution and posing health risks to workers. In contrast, Waterborne Adhesives use water as their primary solvent, reducing or eliminating the need for harmful VOCs. This makes them safer for both workers and the environment, and it allows automotive manufacturers to comply with increasingly strict environmental regulations.

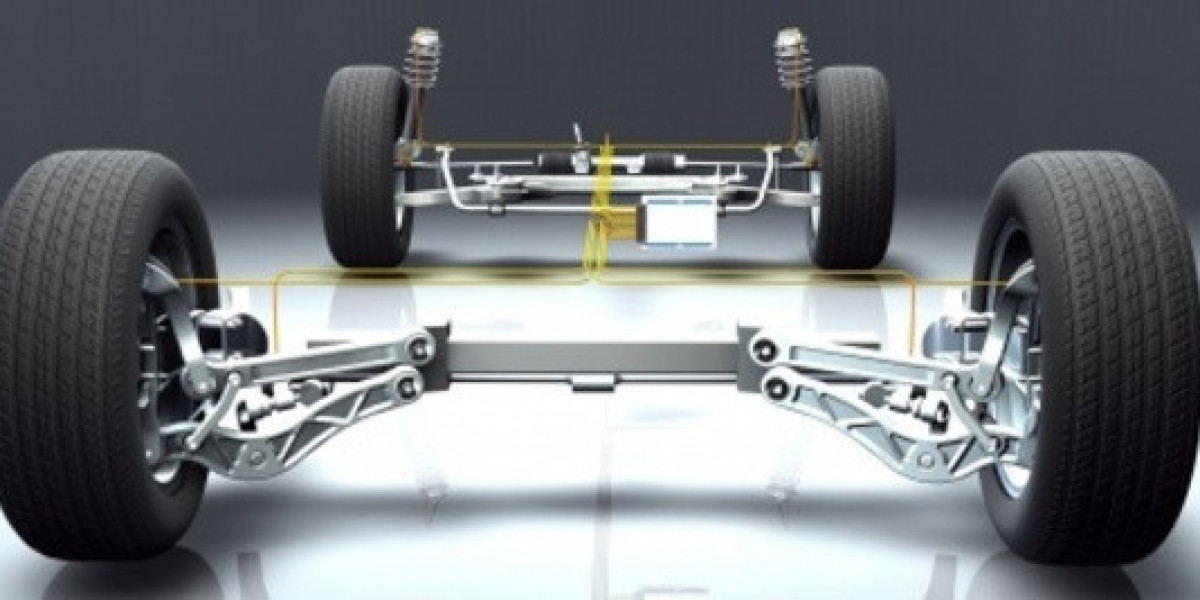

Waterborne Adhesives are commonly used in automotive applications such as interior trim assembly, window bonding, and underbody coatings. These adhesives provide excellent bonding strength and durability, even in demanding conditions such as extreme temperatures, humidity, and vibrations. For example, they are often used to bond vehicle headliners, door panels, and dashboards, where a strong, flexible bond is required. Additionally, Waterborne Adhesives are used in the bonding of composite materials and lightweight components, which are increasingly used in the automotive industry to improve fuel efficiency and reduce emissions.

In addition to their environmental benefits, Waterborne Adhesives offer several performance advantages in automotive manufacturing. They exhibit good resistance to weathering, heat, and chemicals, making them suitable for exterior bonding applications. Furthermore, Waterborne Adhesives provide strong adhesion to a wide range of substrates, including metal, glass, plastic, and rubber. This makes them ideal for the diverse materials used in modern vehicle production.

Another significant advantage is the ability to use Waterborne Adhesives in high-speed, automated manufacturing processes. These adhesives can be easily applied using automated systems, such as robotic arms or spray systems, ensuring uniform coverage and consistent bond strength. This enhances production efficiency and reduces labor costs in manufacturing plants.

Finally, the low viscosity of Waterborne Adhesives allows for easy application and quick drying times, which improves the overall speed of the production process. This is particularly important in the fast-paced automotive industry, where reducing production time can lead to significant cost savings.

Waterborne Adhesives are becoming an increasingly important component in automotive manufacturing. Their ability to provide strong, durable bonds while being environmentally friendly makes them a valuable alternative to traditional solvent-based adhesives. As the automotive industry continues to prioritize sustainability and efficiency, Waterborne Adhesives are likely to play an even more significant role in the future of vehicle production.

Get More Insights On-Waterborne Adhesives

Get This Report In Japanese

Get This Report In Korean

About Author:

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)