Cleaning Marine Surfaces

One of the most important uses of marine chemicals is for cleaning various surfaces that are exposed to saltwater in the marine environment. Whether it's boat hulls, decks, engines or other equipment, regular cleaning is necessary to remove saltwater deposits, algae growth and other marine organisms. Proper cleaning prevents corrosion and extends the lifespan of materials. There are various marine cleaning chemicals available for different surfaces.

For fiberglass and gelcoat surfaces on boats, dedicated Marine Chemicals fiberglass cleaners are effective for breaking down salts, dirt and organic matter. They usually contain surfactants to cut through contaminants without scratching the surface. When used with a brush or sponge, they safely remove buildup from fiberglass hulls, decks and superstructures. Many work on painted surfaces as well. For tough stains like algae or grease, stronger marine cleaners may be needed. Always test products in an inconspicuous area first.

For painted boat surfaces like the cabin top or trim, using the wrong cleaning product can damage the finish. Marine paint cleaners are gentler formulas that safely lift dirt and film without stripping away the paint layer. They work to restore the shine without scrubbing too hard. For maintenance washing throughout the boating season, a low-pH boat wash is suitable for keeping surfaces fresh between deeper cleanings. Pay attention to the product's recommendations based on paint type.

Marine engine and equipment parts require degreasers that tackle oil, grease and carbon deposits effectively. Biodegradable solvent-based engine degreasers cut through heavy grime, even baked-on carbon from pistons and valves. They assist in maintenance tasks like cleaning carburetors, spark plugs and other components during service. Choose a product compatible with materials like aluminum, steel, rubber, plastic and other engine materials. Check labels and do patch tests on less visible areas first.

Corrosion Prevention

A key role of marine chemicals involves protecting boat and equipment surfaces from corrosion caused by exposure to saltwater. The salts in seawater act as an electrolyte that accelerates oxidation reactions with metal substrates like steel and aluminum alloys. With proper application of corrosion inhibitors, however, the damage can be minimized or prevented altogether.

For steel or metal surfaces below the waterline, an onboard zinc anode acts as a sacrificial anode to protect the metal by corroding first. Additional protection comes from applying a marine-grade epoxy or polyurethane paint formulated with corrosion inhibitors. These maintain a barrier coating and include chemical additives that ward off electrolytic reactions. Periodic touch-ups are needed where the coating is damaged.

On engines, corrosion inhibitor sprays and lubricants help prevent damage to metal surfaces from condensation and corrosive vapors in the bilge. Apply them onto linkage rods, cables and other components. For electrical connections and accessories below deck, marine-grade corrosion preventative compounds fill gaps and form a protective sealant film. Check them regularly for reapplication when signs of deterioration appear.

For engines, water drainage systems and air conditioners that discharge overboard, chlorine tablet feeds minimize marine growth by maintaining a small level of active chlorine in the bilge water or discharge. They kill bacteria and algae before they take hold. Periodic shock treatments with higher chlorine levels purge biofilms in pipes and coils. Monitor chlorine residuals and change feed rates or tablets as needed.

Marine Growth Control

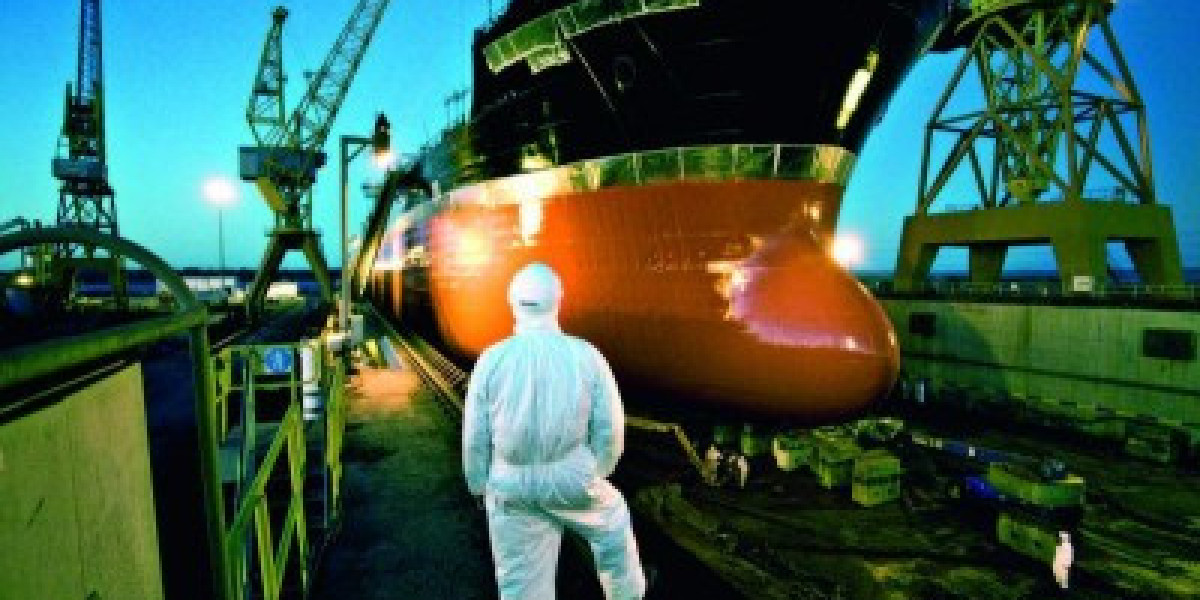

Controlling marine growth like algae, barnacles and mollusks on boat hulls is vital for performance, fuel efficiency and antifouling. Both nontoxic and biocide-based antifouling paints are available for preventing slime, weeds and hard shelled organisms from attaching and slowing the boat down. High-performance ablative or hard antifouling paints require periodic shore-side cleaning and new bottom paint applications every 1-2 years depending on boat use. In between haul-outs, boat owners can blast marine growth off hulls safely with non-chlorinated enzymatic cleaners.

For props and running gear, specialty propeller paints are formulated to release copper or other fouling release agents over time. They maintain smooth surfaces and minimize growth without sanding off layers like traditional bottom paint. For aluminum or other metal alloys prone to pitting, sacrificial zinc anode strips around sterndrives, outdrives and shafts prevent galvanic corrosion and growth attachment in those areas.

On piers, buoys, sea walls and other fixed structures near the waterline, marine growth release agents and coatings prohibit attachment of algae, mollusks and other pests. Silicone-based antifoulant coatings produce a slick surface that starves growth of attachment points. Biocide-containing coatings are also available depending on the area's regulations for toxin discharge into surrounding waters. Follow product directions carefully to avoid harming marine environments.

Maintaining Water Quality

Marine chemicals play an essential part in maintaining water quality aboard boats and in marinas or bodies of water. As water circulates through livestock holding tanks, fishpond filters, deck drains and other systems, levels of contaminants like ammonia or nitrogenous waste rise. Biological additives for lives wells or aquaculture help control these compounds through nitrification and promote clear, healthy water. For toilets, specialized holding tank treatments contain bacteria to break down waste and neutralize odors as the blackwater contains. They minimize pump-outs and extend tank capacity between emptying.

Get This Report in English Language: Marine Chemicals

Get This Report in Japanese Language: マリンケミカルズ

Get This Report in Korean Language: 해양 화학

About Author:

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.

(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)