Introduction:

Encapsulated cables are essential to many different businesses since they can be used as conduits for communication signals, electrical wiring, and other purposes. The form of the tube used to house the wire is an important factor in the design of encapsulated cables. Both square and round tubes have advantages, but which one is better depends on the particular needs of the application. We will examine the benefits of round versus square tube encased cables in this in-depth analysis, taking into account factors like overall performance, space utilization, structural integrity, and ease of installation.

Structural Integrity and Durability:

One of the main factors to consider when deciding between round and square tubing for encapsulated cables is the structural strength and durability offered by each design.

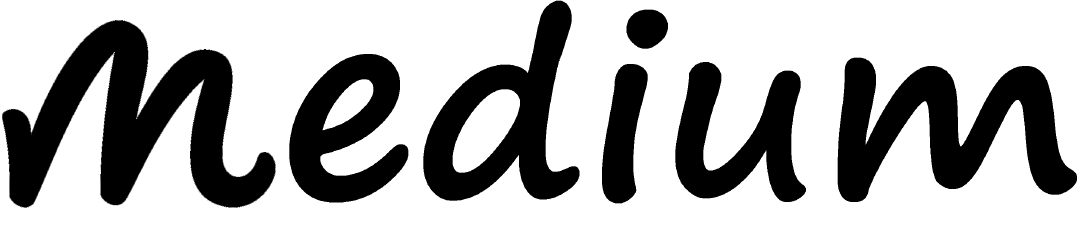

Round Tubing:

Round tubing provides excellent structural integrity thanks to its even stress distribution. The circular shape naturally disperses external forces uniformly around the circumference, making round tubing resistant to bending and torsional stress. This feature is especially beneficial in scenarios where the cable might undergo bending or flexing, such as in robotic arms or moving machinery.

Furthermore, the absence of sharp corners in round tubing reduces the risk of stress concentrations, which can cause material fatigue and premature failure. This makes round tubing encapsulated cables well-suited for high-stress environments where reliability is crucial, like in aerospace, automotive, and industrial applications.

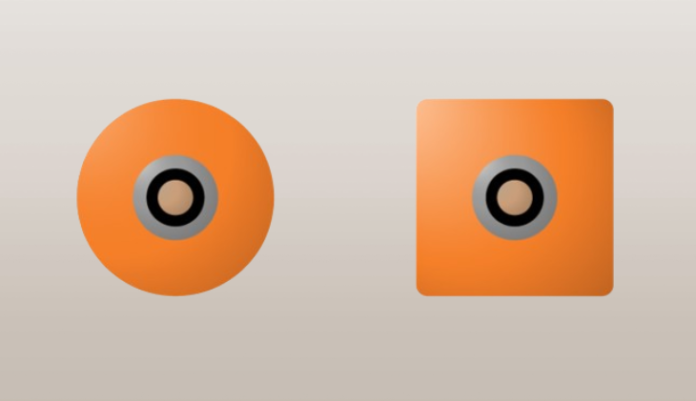

Square Tubing:

On the other hand, square tubing offers increased resistance to compression and lateral forces compared to round tubing. The flat surfaces of square tubing provide a larger contact area when securing or mounting the cable, leading to better stability and load-bearing capacity. This makes square tubing encapsulated cables ideal for situations where the cable may face heavy loads or pressure, such as in structural support systems or cable trays.

Moreover, the straight edges of square tubing facilitate easy stacking and interlocking, enabling efficient use of storage space during transportation and installation. The rigid geometry of square tubing also lends itself well to modular construction and assembly, allowing for seamless integration into prefabricated structures or enclosures.

Ease of Installation and Maintenance:

When comparing round and square tubing encapsulated cables, it’s important to consider the ease of installation and maintenance.

Round Tubing:

Round tubing cables offer flexibility and ease of maneuverability during installation, thanks to their smooth, curved surfaces. The absence of sharp edges reduces the risk of abrasion or snagging, making it easier to route the cable through tight spaces or around obstacles. This flexibility is particularly beneficial in scenarios where the cable needs to navigate complex pathways or conform to curved surfaces, like in building wiring or cable harnesses.

Additionally, the symmetrical design of round tubing allows for simple rotation and orientation adjustments during installation, reducing the need for specialized tools or fittings. This simplifies the assembly process, cutting down on installation time and labor costs. As a result, round tubing cables are often preferred for projects with tight deadlines or budget constraints.

Square Tubing:

Square tubing cables excel in applications that require precise alignment and positioning. The flat surfaces and right angles of square tubing make mounting and attachment secure, ensuring stable cable routing without the risk of shifting or misalignment. This is particularly useful in structured wiring systems or cable management setups where maintaining organized cable runs is crucial for efficient operation and accessibility.

Furthermore, the consistent geometry of square tubing simplifies the installation of accessories like connectors, brackets, and junction boxes. These components can be easily secured to the straight edges without the need for extra adapters or modifications, streamlining the integration of additional parts and enhancing the overall reliability and functionality of the cable system.

Space Utilization and Aesthetic Considerations:

Besides considering structural integrity and ease of installation, the decision between round and square tubing encapsulated cables may also be influenced by space utilization requirements and aesthetic considerations.

Round Tubing:

Round tubing cables excel in space utilization efficiency in scenarios where minimizing footprint and maximizing clearance are crucial. The circular cross-section allows for tighter bends and curves without compromising internal space, making round tubing ideal for confined or densely populated environments.

Moreover, the smooth, curved profile of round tubing enhances visual aesthetics and reduces the likelihood of dust accumulation or debris buildup, maintaining a clean and professional appearance over time. This makes round tubing encapsulated cables well-suited for architectural and interior design applications where aesthetics are vital.

Square Tubing:

Square tubing cables are preferred in situations where maximizing surface area for mounting or attachment is key. The flat surfaces of square tubing offer ample space for securing accessories, labels, or identification markers, enhancing organization and traceability within the cable system.

Additionally, the geometric symmetry of square tubing aligns well with modular design principles, enabling standardized component sizes and interlocking configurations. This promotes efficient use of space in storage racks, cable trays, or equipment enclosures, optimizing spatial layout and minimizing wasted area.

Conclusion:

In conclusion, the choice between round and square tubing encapsulated cables depends on various factors, including structural requirements, installation considerations, space utilization constraints, and aesthetic preferences. Round tubing provides excellent structural integrity, flexibility, and space efficiency, making it suitable for applications where reliability, maneuverability, and compactness are crucial. Square tubing, on the other hand, offers enhanced load-bearing capacity, precise alignment, and efficient use of mounting space, making it ideal for applications prioritizing stability, organization, and modularity.

By carefully assessing the specific needs and constraints of each project, engineers and designers can choose the most appropriate tubing shape for encapsulated cables, ensuring optimal performance, longevity, and functionality across a wide range of applications and industries.