views

In today’s international digital design and precision production, producers increasingly depend upon virtual tools to streamline their operations. One such innovation is Cut List Optimization Software, a specialized program designed to reduce waste and enhance performance while cutting materials like wood, metallic, plastic, and glass. The software program generates cutting diagrams based totally on cloth dimensions and favored elements, assisting users limit offcuts and make the most in their inventory. While its software in easy layouts is well known, many professionals marvel at whether it is able to also accommodate greater tricky and complex tasks. The short solution is yes—this software has advanced substantially to satisfy the needs of quite detailed and multi-layered production tasks.

2. Features That Enable Handling of Complex Layouts

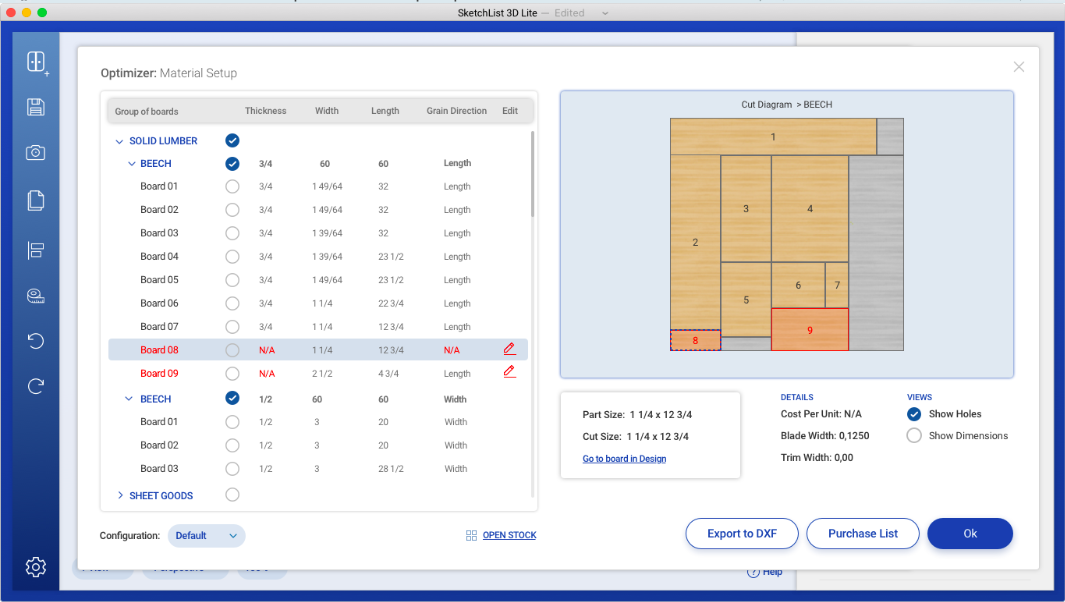

Complex initiatives typically involve more than one cloth type, custom part sizes, complicated joining necessities, and several constraints consisting of grain direction or kerf width. Cut list optimization software is constructed to account for these variables. Advanced systems now include configurable rulesets that allow customers to define constraints and priorities that match task specs. Whether it is nesting curved cuts, adjusting for unique patterns, or compensating for fabric flaws, the software program adapts to these demanding situations. Some systems even permit importing designs immediately from CAD applications, in addition reducing the margin for error and growing the software program’s potential to manipulate complexity.

3. Multi-Material and Multi-Project Capabilities

In huge-scale operations, manufacturers do not often work with a single type of material or a single process at a time. Modern reduce list optimization solutions are ready to handle a couple of materials simultaneously. They can system extraordinary thicknesses, grades, and finishes, all at the same time as keeping correct stock counts and minimizing wastage. Additionally, many applications can juggle multiple initiatives inside an unmarried consultation. This is specially useful for batch processing, where numerous objects across several tasks must be cut from shared stock. The software analyzes all reducing necessities together, optimizing across initiatives rather than treating each as a siloed venture.

4. Integration with Design and Production Tools

Another key element that helps the software program's potential to manage complicated initiatives is its integration with upstream and downstream equipment. Most superior structures are designed to work in tandem with layout software like AutoCAD or SolidWorks, taking into consideration seamless statistics transfer from layout to manufacturing. On the opposite end, they regularly integrate with machine controllers, CNC structures, and saw measuring gear, ensuring that the cut plans are carried out precisely. This holistic integration guarantees consistency and decreases the probability of mistakes, that's important in difficult builds wherein each millimeter matters.

5. Accounting for Real-World Variables

While theoretical reduction plans may be calculated without problems, real-global projects consist of variability together with broken material sections, non-wellknown dimensions, or final-minute design adjustments. Sophisticated cut listing optimization software permits customers to enter these actual-global factors at once into the planning interface. Users can flag unusable regions of a board or panel, and the device will routinely alter the format to compensate. This level of adaptability is essential in complicated jobs where unexpected problems can significantly disrupt timelines if now not quickly addressed.

6. Project Scalability and Version Control

One of the most underrated however essential features in dealing with complex initiatives is scalability. As a task expands in scope—whether through additives or revised specifications—the software program ought to scale without losing performance. Cut list optimization systems are designed to handle big datasets with numerous variables. They also include version control mechanisms that track modifications throughout different iterations of the project. This makes it clean to revert to previous plans if wanted or examine extraordinary strategies for slicing and assembly. The potential to control a couple of revisions whilst preserving clarity and precision is especially valuable in architectural, furnishings, and commercial layout initiatives.

7. User-Defined Prioritization for Better Decision-Making

In complex scenarios, the user may have particular goals, which include minimizing the quantity of cuts, reducing gadget runtime, or maximizing cloth yield. Cut listing optimization equipment offers customizable prioritization settings to align with these desires. Users can outline whether the device should prioritize velocity over efficiency, or vice versa. This functionality is especially crucial while managing tight time limits, budget constraints, or unique purchaser requirements. By adjusting parameters to suit specific venture wishes, the software program affords consequences that are not most effectively technically ideal however additionally strategically aligned with commercial enterprise objectives.

8. Enhanced Visualization and Reporting for Quality Control

The ability to visualise slicing layouts and determine cloth usage via specific reports is some other energy that facilitates the software control of complex tasks. Most current systems offer 2D or even 3-d previews of reduced plans, whole with annotations and measurements. This visualization enables teams to pick out capacity troubles before slicing starts, lowering waste and enhancing first-class control. Moreover, distinct reporting tools track inventory, yield percentages, and component availability, presenting insights that can be shared across departments. These equipment are important for keeping transparency and ensuring that all group participants are aligned, especially in multifaceted tasks that contain numerous degrees and groups.

9. Time and Cost Efficiency in High-Volume Production

Complex projects regularly correlate with excessive manufacturing volumes, in particular in fields like cabinetry, aerospace, or custom fixtures production. In those contexts, time and fee efficiency grow to be paramount. Cut list optimization software extensively reduces the planning time via automating repetitive calculations and diagram technology. This not simplest quickens the setup segment but also reduces system downtime. Additionally, by optimizing fabric utilization, the software immediately contributes to price savings. These time and cost benefits scale with undertaking complexity, making the software program a crucial asset in big and elaborate operations.

10. Continuous Improvement Through Data Analysis and AI

Lastly, the maximum superior variations of this software are now incorporating AI and gadget learning talents. These features analyze beyond initiatives to enhance future performance. For example, the machine would possibly recognize patterns in material waste or routine layout inefficiencies and advocate options. Over time, the software learns from preceding outcomes, permitting better predictions and greater intelligent layouts. This evolving intelligence transforms cut list optimization software from a static planning tool right into a dynamic decision-making assistant. In the context of complex projects, this capability ensures no longer simply performance, but ongoing improvement.

Conclusion: Meeting the Demands of Complexity with Confidence

The demands of modern production and custom fabrication are more intricate than ever. Projects these days involve a huge type of substances, tight tolerances, difficult geometries, and evolving specifications. Cut listing optimization software rises to meet these demanding situations through supplying a flexible, powerful, and sensible solution for fabric planning. It integrates with key equipment, handles real-world complexities, supports scalable project control, and gives you time and fee efficiencies which are critical in high-stakes environments. With the developing integration of AI and IoT technology, the skills of those structures will best enlarge, permitting even extra management and accuracy.

For those in production environments that also depend on physical accuracy during execution, pairing cut list optimization with a dependable saw measuring system ensures that virtual plans translate seamlessly into actual-global results. Together, these technologies form a sturdy environment that empowers groups to address even the most complicated tasks with precision and self assurance.

Comments

0 comment