views

3D Printed Packaging Market Share, Growth Forecast and Key Trends 2032

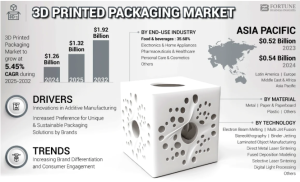

According to Fortune Busines Insights, The global 3D printed packaging market was valued at USD 1.26 billion in 2024 and is projected to reach USD 1.32 billion in 2025, before climbing to USD 1.92 billion by 2032, expanding at a CAGR of 5.45% during the forecast period. Asia Pacific dominated the market in 2024, capturing 42.86% of the global share, driven by strong adoption in food, cosmetics, and consumer goods industries.

The 3D printed packaging industry is transforming the packaging landscape with its ability to deliver sustainable, customized, and cost-efficient solutions. Unlike traditional methods, additive manufacturing enables personalized designs, rapid prototyping, reduced material waste, and shorter production cycles, making it a game-changer for businesses. Growing demand for eco-friendly packaging, coupled with the rise of luxury, pharmaceutical, and food & beverage sectors, is fueling market expansion.

With innovation, sustainability, and brand differentiation at the forefront, the 3D printed packaging market is set to witness strong growth through 2032, reshaping how companies design and deliver packaging solutions worldwide.

Request a FREE Sample Copy: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/3d-printed-packaging-market-111126

List of Key 3D Printed Packaging Companies Profiled:

- Stratasys Ltd. (U.S.)

- 3D Systems Corporation (U.S.)

- Materialise NV (Belgium)

- EOS GmbH (Germany)

- SLM Solutions Group AG (Germany)

- Nexa3D (U.S.)

- Protolabs Inc. (U.S.)

- GE Additive (U.S.)

- Carbon, Inc. (U.S.)

- Desktop Metal, Inc. (U.S.)

Market Growth Drivers

-

Customization & Personalization – 3D printing enables brand owners to design packaging with unique textures, shapes, and labels, improving consumer engagement.

-

Sustainability Focus – The use of biodegradable and recyclable 3D printing materials aligns with the global shift toward eco-friendly packaging.

-

Rapid Prototyping & Efficiency – Businesses can quickly design, test, and modify packaging without high tooling costs.

-

E-commerce Expansion – The surge in online shopping is pushing demand for innovative, lightweight, and protective packaging.

-

Technological Advancements – Development in additive manufacturing, smart packaging, and biopolymers is accelerating adoption.

Market Segmentation

By Material

-

Bioplastics

-

Polymers (PLA, PET, ABS)

-

Paper-based composites

-

Others

By Application

-

Food & Beverages Packaging

-

Pharmaceutical & Healthcare Packaging

-

Cosmetics & Personal Care Packaging

-

Electronics & Consumer Goods Packaging

By Region

-

North America – Early adoption of 3D printing in packaging with strong R&D investment.

-

Europe – Strong focus on sustainability and eco-friendly packaging regulations.

-

Asia-Pacific – Fastest-growing market driven by manufacturing hubs in China, Japan, and India.

-

Rest of the World – Emerging markets adopting 3D printed packaging in niche industries.

Key Industry Trends

-

Growing use of smart 3D printed packaging with QR codes, RFID, and NFC tags for better traceability.

-

Increasing collaboration between 3D printing companies and packaging manufacturers.

-

Adoption of on-demand packaging production models to reduce warehousing costs.

-

Rising demand for luxury and premium packaging solutions in cosmetics and high-end beverages.

Competitive Landscape

Leading players in the 3D printed packaging market are investing in R&D, partnerships, and eco-friendly material innovation. Companies are also focusing on scaling production technologies to meet the growing demand for mass customization and sustainable packaging.

3D printed packaging refers to the creation of packaging materials using additive manufacturing, where objects are built layer by layer from a digital model. The market is witnessing strong growth, driven by advancements in 3D printing technologies and the increasing demand for sustainable and customized packaging solutions across industries. Both businesses and consumers are seeking unique designs that reflect individual preferences and brand identity. With its exceptional design flexibility, 3D printing enables the production of intricate, personalized packaging that traditional methods often cannot achieve. This trend is particularly evident in sectors such as cosmetics, luxury goods, and food & beverages, where packaging plays a crucial role in enhancing product appeal.

The 3D printed packaging market is set to expand significantly, supported by sustainability mandates, digital manufacturing innovations, and consumer-driven personalization trends. As industries continue to embrace additive manufacturing, the market is projected to play a crucial role in shaping the future of packaging.

Information Source: https://www.fortunebusinessinsights.com/3d-printed-packaging-market-111126

KEY INDUSTRY DEVELOPMENTS:

- In May 2024, Unilever—the consumer goods giant housing brands, such as Dove, Persil, and Ben & Jerry’s—adopted additive manufacturing to fulfill its prototyping requirements. Instead of printing prototypes of its product packaging directly, it has opted for a different approach by utilizing SLA 3D printing to create blow molding tools. This strategy, implemented in collaboration with packaging producer Serioplast and Formlabs, has significantly reduced product development timelines for new plastic bottle packaging and tooling expenses.

- In April 2024, Baralan partnered with 3D printing expert Stratasys and coatings specialist ICA to introduce GP3DPrint, a water-soluble 3D decoration service for cosmetic packaging. The initiative makes personalized, distinctive, and high-end decor available to a broader range of brands.

Comments

0 comment