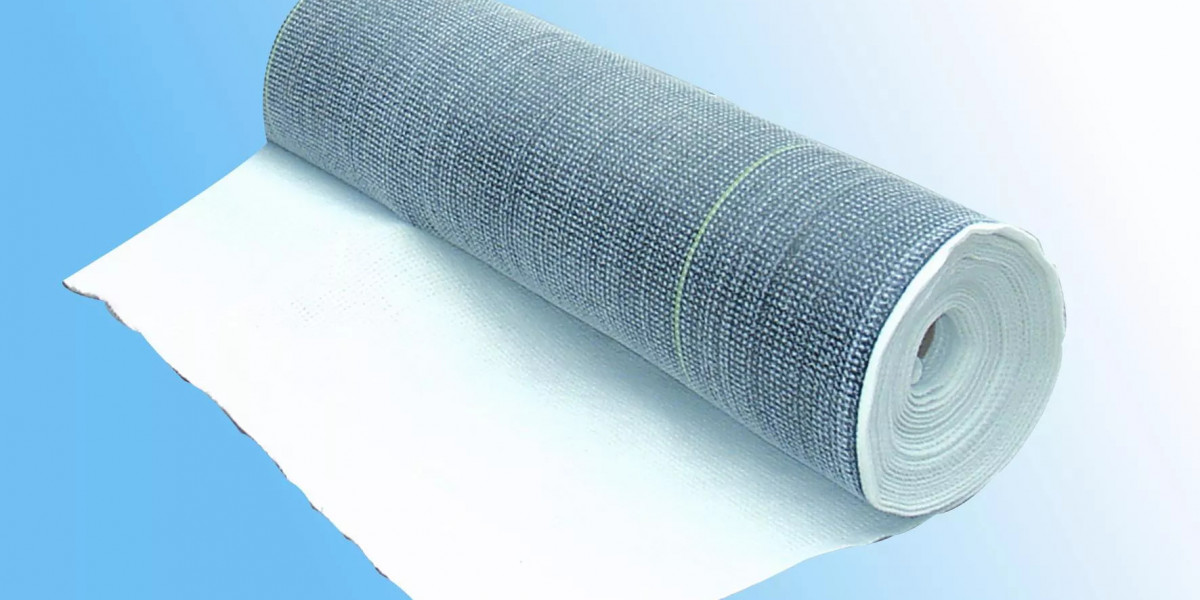

In modern environmental engineering, managing waste and preventing contamination are critical priorities. A geosynthetic clay liner (GCL) is a highly effective solution for creating secure barriers in various containment applications. These liners combine natural bentonite clay with geotextiles or geomembranes, forming a flexible and reliable sealing system. Used in projects ranging from landfill construction to water reservoirs, GCLs are an innovative way to ensure environmental safety while maintaining efficiency.

What Are Geosynthetic Clay Liners?

Geosynthetic clay liners are engineered barriers made by layering bentonite clay between two sheets of geotextile fabric. The clay expands when hydrated, creating a dense, impermeable layer that prevents the migration of liquids and contaminants. These liners are widely used in environmental projects due to their versatility and cost-effectiveness.

Advantages of Using Geosynthetic Clay Liners

Superior Containment Performance

GCLs offer exceptional impermeability, making them ideal for applications that require reliable containment, such as landfill liners, wastewater lagoons, and mining operations. The natural swelling property of bentonite clay ensures a tight seal that adapts to site conditions.

Eco-Friendly Solution

Geosynthetic clay liners use natural bentonite clay, which is an environmentally friendly material. They provide a sustainable alternative to traditional clay liners, reducing the carbon footprint associated with excavation and transportation of natural clay.

Cost-Effective Installation

GCLs are lightweight and easier to install than compacted clay liners, which require extensive labor and heavy equipment. Their prefabricated structure allows for faster deployment, reducing overall project costs and timelines.

Self-Healing Properties

One of the most unique benefits of GCLs is their self-healing ability. If the liner is punctured, the bentonite clay expands to fill the void, maintaining the liner's integrity and performance.

Versatility Across Applications

Geosynthetic clay liners can be used in a variety of settings, including landfills, ponds, canals, and industrial containment systems. Their adaptability makes them suitable for complex projects with varying site conditions.

Space-Saving Design

Compared to traditional clay liners, GCLs require less space to achieve the same level of containment. This is particularly advantageous in areas where space is limited or where maximizing storage capacity is essential.

Resistance to Harsh Conditions

GCLs are engineered to withstand chemical exposure, temperature fluctuations, and other environmental stresses. This durability ensures long-term performance in challenging applications, such as hazardous waste containment.

Minimal Maintenance Requirements

Once installed, GCLs require little to no maintenance. Their durable design and self-healing properties minimize the risk of failures, providing a reliable and low-maintenance solution for environmental protection.

Applications of Geosynthetic Clay Liners

Landfill Liners and Caps: Prevents leachate from contaminating the surrounding soil and groundwater.

Water Containment: Provides effective lining for reservoirs, ponds, and canals.

Mining Operations: Offers a barrier for tailings ponds and containment of by-products.

Wastewater Treatment: Used in lagoons and other treatment facilities to ensure secure containment.

Why GCLs Are Critical for Environmental Protection

As environmental regulations become more stringent, the demand for reliable containment solutions continues to grow. GCLs provide an effective way to meet these requirements, ensuring that projects comply with environmental standards while protecting natural resources. Their performance, durability, and cost-effectiveness make them a preferred choice for engineers and environmental managers alike.

A geosynthetic clay liner is an innovative and practical solution for achieving secure containment in various environmental applications. From superior impermeability to eco-friendly materials and cost savings, GCLs offer a host of advantages that make them indispensable for modern construction and waste management projects. By incorporating GCLs, you can safeguard the environment while ensuring the success of your project.