According to the new market research report "Technical Textile Market by Material (Natural Fiber, Synthetic Polymer, Metal, Mineral, Regenerated Fiber), by Process (Woven, Knitted, Non-woven), by Application (Mobiltech, Indutech, Protech, Buildtech, Packtech), and Region - Global Forecast to 2025", published by MarketsandMarkets™, the global Technical Textile Market size is projected to grow from USD 164.6 billion in 2020 to USD 222.4 billion by 2025, at a CAGR of 6.2% from 2020 to 2025.

PDF Download: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=1074

Browse and in-depth TOC on "Technical Textile Market"

201 - Tables

56 - Figures

243 – Pages

View detailed Table of Content here - https://www.marketsandmarkets.com/Market-Reports/technical-textile-market-1074.html

Technical Textile Market Dynamics

Driver: Increasing adaptability and awareness of the products

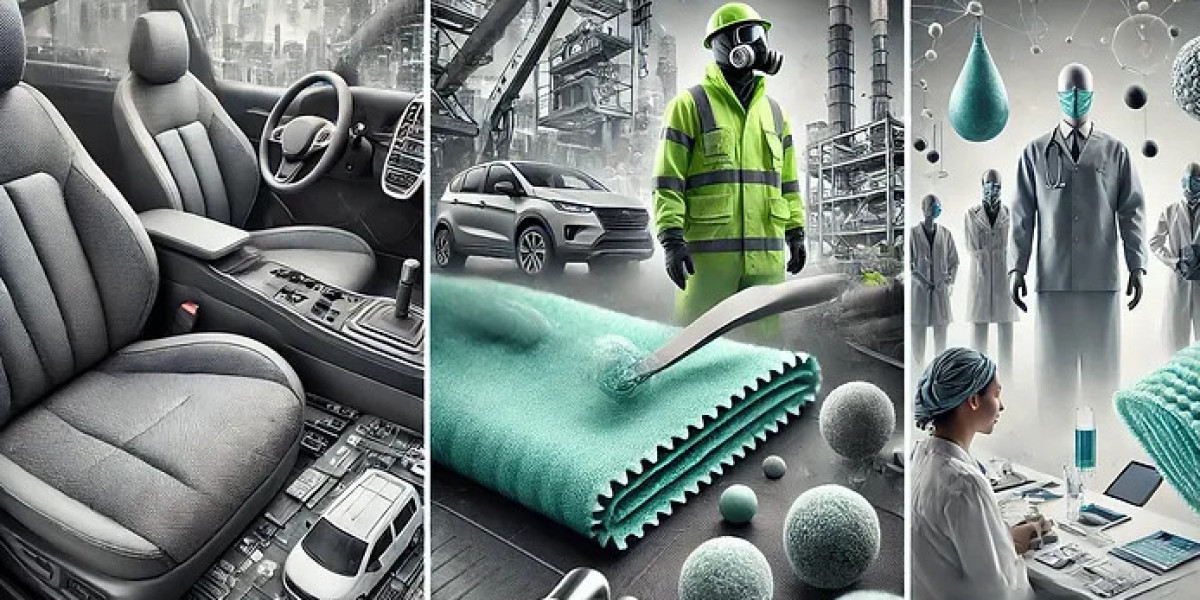

Growing awareness about the superior functionality and application of technical textiles is encouraging the higher consumption of technical textiles and related products. The increasing adaptability of unconventional value in textiles has influenced traditional manufacturing to escalate the pace of innovation, and upgrade the traditional fibers by contributing to technical textile development. The change is attributed to accelerated demand for product which offers flexibility, durability and offers superior functionalities such as personal safety, high strength, and light weight.

Restraint: High cost of finished products affect s the pricing structure of the intermediate industry

The complex procedure of technical textiles manufacturing is a restraint to the market participants as it requires advanced infrastructure which is cost sensitive. Along with this, high cost of raw material procurement inevitably raises the total cost of finished product to an extent where the manufacturers are left with limited opportunities for profit margin. On the other hand, the high price of technical textiles products affects the pricing structure of the intermediate industries which makes the final product available to the customer.

Opportunity: Proliferation of new technologies

With the technological enhancement, the textile industry has witnessed high growth in most of its product segments, especially for technical textiles. New technologies are expected to bring down the production cost, thus making manufacturing of technical textile commercially feasible. The improved technologies in spinning, weaving & knitting segment, such as melt spinning, thermo-forming, and three dimensional weaving & knitting wet spinning, have made it possible to produce technical textiles fibers with functional properties required for technical textiles. The production of high performance fibers is largely grounded in technologically advanced countries such as the US, Japan, Canada, and some European countries and is progressing in developing countries such as India, China, and Korea.

Challenge: Varying environmental mandates across regions

Environmental mandates regarding the chemical use in industry differ across various countries; this makes it difficult for manufacturers to adjust the usage of textile manufacturing materials according to the region specific regulations. Environmental mandates are rampant on the final consumer, government, and intermediate industry as well. Consumers are showing more interest towards biodegradable and eco-friendly materials; the intermediate industry tries to ensure that the product does not increase the cost of the final product to an extent that they lose out on market share. Governments in Europe, North America, and Asia have developed regulations strictly pertaining to the chemical industry with regards to their recycling rates, container deposits, and wastes.

The market has grown exponentially in the last few years, and this trend is projected to continue. The growing awareness about the superior functionality and application of technical textiles encourages the higher consumption of technical textiles and related products. Furthermore, growth in the automobile, construction, healthcare, packaging, and various other sectors has generated new opportunities for technical textiles.

Sample Pages: https://www.marketsandmarkets.com/requestsampleNew.asp?id=1074

The nonwoven segment is expected to grow at the highest CAGR during the forecast period

Based on process, the nonwoven segment is expected to be the fastest-growing during the forecast period. Additionally, advancements in weaving technology such as 3D weaving are expected to drive the technical textile segment during the forecast period.

The mobiltech segment is estimated to account for the largest share in the Technical Textile Market in 2019

Based on application, the mobiltech segment lead the Technical Textile Market. Mobiltech covers technical textiles used in automobiles, aircrafts, railways, and shipbuilding such as nylon tire cord fabrics, seat covers, seat belts, cabin filters, tufted carpet, upholstery, and others.

The APAC region is projected to account for the largest share in the Technical Textile Market during the forecast period.

The APAC region is projected to lead the Technical Textile Market, in terms of both value and volume from 2020 to 2025. Higher domestic demand, along with the availability of low-cost labor, makes this region the most attractive market for technical textile manufacturers. Hence, the market players are focusing on this region to gain a larger share and increase their profitability. Factors such as improving global economy, expanding working population, and rising domestic demand for hygiene products are expected to boost the market for technical textile.

Inquire Before Buying: https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=1074

Technical Textile Market Key Players

Key players operating in the Technical Textile Market include Asahi Kasei (Japan), Kimberly Clarke (US), Berry Global Group (US), DuPont (US), Mitsui Chemicals (Japan), Freudenberg & Co. (Germany), Low & Bonar (UK), Huntsman (US), Toyobo Co. (Japan), Milliken & Company (US), SRF Limited (India), Koninklijke Ten Cate (Netherlands), and International Textile Group (US). These players have adopted various growth strategies to expand their global presence and increase their market share. Mergers & acquisitions, expansions & investments, agreements & partnerships, and new product launches are some of the major strategies adopted by key players operating in the Technical Textile Market.

Asahi Kasei (Japan) is a leading manufacturer of apparel material & products, technical textiles & nonwovens, plastic materials, chemicals, and construction materials. Strong global presence and adoption of growth strategies such as investments & expansions and new product launches have ensured its leading position in the market. The company’s technical textiles business deals with a wide range of materials and related products such as cotton, yarns, textiles, and processed products. The group focuses on new product development through research & development activities and innovations. In 2017, Asahi Kasei Fibers & Textiles expanded its capacity to produce Lamous, a high-quality microfiber suede. It is used in a wide variety of applications such as furniture upholstery, automotive interiors, IT accessories, apparel, and industrial materials.

Low & Bonar (UK) is another key player in the technical textile market. The company is engaged in the production of nonwovens for the hygiene, healthcare, geo-synthetics wipes, technical specialties, and building sectors. The company focuses on improving its customer value and expanding in emerging markets by establishing a market-driven product portfolio, upgrading supply chain capabilities, and expanding its presence through acquisitions. For instance, Low & Bonar started its high-performance technical textiles production in Changzhou, to expand its position in the Asian market and become a global leader in the carpet tile backing and automotive markets.