The cap applicator market has witnessed significant growth in recent years owing to increased demand from the food & beverage industry. Cap applicators help in sealing containers quickly and efficiently during packaging processes. They help avoid manual capping errors and ensure high-speed production lines. Cap applicators provide an economical and reliable solution for capping bottles on a large scale. The growing demand for packaged and ready-to-consume food & drinks has propelled the need for cap applicators.

The global automated cap applicator market is estimated to be valued at US$ 797.9 million in 2025 and is expected to exhibit a CAGR of 3.6% over the forecast period 2025 to 2032.

Key Takeaways

Key players operating in the cap applicator market are Tetra Pak, Krones AG, KHS GmbH, Arpac LLC, and Bosch Packaging Technology.

Growing food & beverage industry in emerging economies of Asia Pacific and Latin America presents lucrative opportunities for market players.

Cap Applicator Market Demand in technological advancements such as smart cap applicators using Internet of Things (IoT) connectivity and machine learning algorithms are gaining popularity.

Market drivers

Increased automation in the packaging industry has led to higher demand for cap applicators. Cap applicators help improve production throughput and reduce operational costs. Growing consumer preference for product packaging and concerns regarding product safety and tampering have further fueled the need for reliable capping solutions. Stringent regulations regarding packaged food safety also drive the cap applicator market.

Current Challenges in Cap Applicator Market

The cap applicator market is facing various challenges due to changes in packaging regulations and supply chain disruptions caused by the pandemic. Stringent packaging rules regarding material usage and recycling policies have increased compliance issues for manufacturers. Further, labor shortages and delays in raw material procurement have negatively impacted production schedules. Changing consumer preferences for sustainable and eco-friendly packaging also poses a challenge to use traditional cap applicator designs. Development of innovative, low-cost applicators suitable for various caps and containers remains a key focus area to boost adoption rates across industries.

SWOT Analysis

Strength: Cap applicators offer high-speed capping ability and allow batch processing of large product volumes. Automated designs ensure consistent cap placement with minimal human errors.

Weakness: High initial investment requirements for automated equipment limits uptake among small players. Upgrades needed to match evolving packaging formats increase operational costs.

Opportunity: Growing demand for single-serve and portable packaging drives need for applicators compatible with narrow neck bottles and specialty containers. Demand from pharmaceutical and personal care industries presents new revenue avenues.

Threats: Stiff competition from alternative sealing techniques like heat induction poses pricing pressure. Stringent environmental norms can curb plastic cap usage and threaten long-term market prospects.

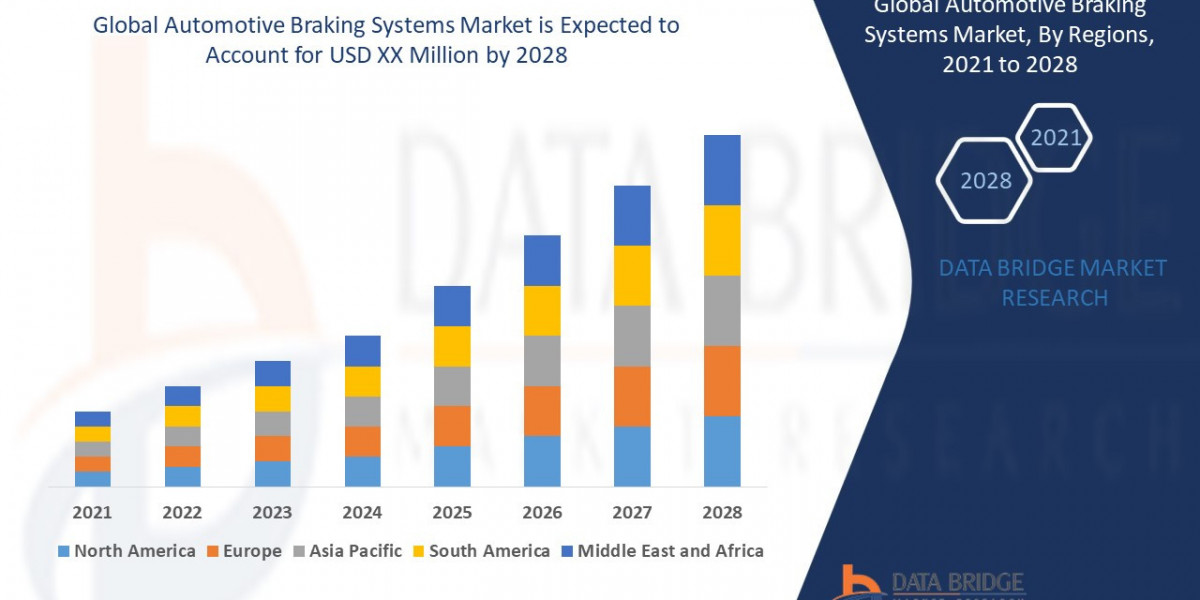

Geographical Regions

North America currently holds the largest share of the global cap applicator market in terms of value owing to robust demand from food and beverage processing industries. Europe follows in terms of market size on account of strong packaging sector and presence of leading applicator suppliers.

The Asia Pacific region is anticipated to register the fastest growth during the forecast period driven by surging industrial activities, population growth and rapid urbanization in China, India and other emerging countries. Establishment of new manufacturing facilities by multinational companies further propels the regional market.

Get This Report in Japanese Language: キャップアプリケーター市場

Get This Report in Korean Language: 캡 어플리케이터 시장

About Author:

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement. (LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)