In the world of manufacturing, precision and efficiency are paramount. Industrial laser engravers have revolutionized the way we approach marking and engraving tasks across various sectors. This article explores the features, types, applications, and advantages of industrial engraver, highlighting their significance in modern production processes.

What is an Industrial Laser Engraver?

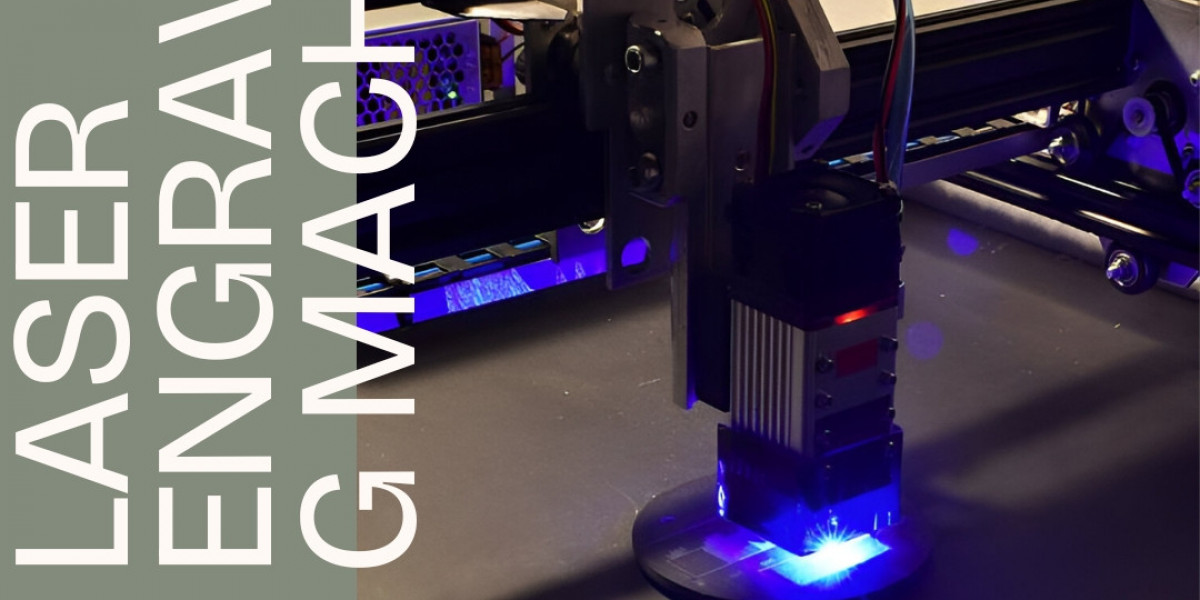

An industrial laser engraver is a specialized tool designed to mark or engrave materials using a concentrated laser beam. This technology relies on the ability to vaporize or etch the surface of different substrates, allowing for intricate designs and precise markings. Whether used in automotive manufacturing, electronics, or jewelry making, these engravers provide unmatched accuracy and speed.

Key Features of Industrial Laser Engravers

High Precision

Industrial laser engravers are renowned for their ability to create detailed and intricate designs. With resolutions reaching up to 8K, they ensure that every marking is crisp and clear, making them ideal for applications requiring high accuracy.Versatility

These machines can work with a wide range of materials, including metals, plastics, glass, and ceramics. This versatility makes them suitable for various industries, from automotive to medical equipment manufacturing.Speed and Efficiency

Laser engravers operate at impressive speeds, significantly reducing the time required for marking compared to traditional methods. This efficiency translates into higher productivity and faster turnaround times for projects.Low Maintenance

Many industrial laser engravers, particularly fiber lasers, require minimal maintenance due to their solid-state design and fewer moving parts. This results in less downtime and lower operational costs over time.Customization Options

Users can easily upload custom designs and modify parameters such as power and speed, allowing for personalized markings tailored to specific needs. This capability is particularly beneficial for branding and product differentiation.

Types of Industrial Laser Engravers

CO2 Laser Engravers

CO2 lasers are widely used for engraving non-metal materials like wood, acrylic, and glass. They produce a high-quality finish and are ideal for applications requiring fine details.Fiber Laser Engravers

Fiber lasers are highly efficient and suitable for marking metals and certain plastics. They offer speed and precision, making them a preferred choice for industries requiring high-quality results.YAG Laser Engravers

YAG (Yttrium Aluminum Garnet) lasers are commonly used for cutting and engraving metals. They provide high power and efficiency, making them suitable for demanding applications in various sectors.

Applications of Industrial Laser Engravers

Automotive Industry

Industrial laser engravers play a crucial role in marking VINs (Vehicle Identification Numbers) and branding components. They enhance traceability and ensure compliance with industry standards.Electronics

In the electronics sector, these machines are used to engrave serial numbers, logos, and barcodes on circuit boards and casings, facilitating easy identification and compliance with regulations.Medical Equipment

Precision is critical in medical device manufacturing. Laser engravers mark essential information directly onto devices, improving traceability and ensuring compliance with safety regulations.Jewelry Making

Jewelers utilize laser engravers to create intricate designs and personalize items. The ability to engrave fine details enhances the uniqueness of each piece, adding value for customers.

Advantages of Using Industrial Laser Engravers

Cost-Effectiveness

While the initial investment may be high, industrial laser engravers reduce material waste and labor costs in the long run. Their durability and longevity also contribute to cost savings.Enhanced Productivity

The speed and efficiency of laser engravers allow businesses to complete projects faster, increasing overall productivity and enabling them to meet tight deadlines.High-Quality Results

The precision of laser engravers ensures that markings are permanent and resistant to wear, maintaining their quality over time. This reliability is essential for industries reliant on traceability.

Conclusion

In summary, industrial laser engravers represent a vital investment for businesses seeking to enhance precision and efficiency in their operations. With their versatility, speed, and accuracy, these machines are invaluable across various sectors, from automotive to jewelry making. By embracing laser engraving technology, companies can improve their production processes, reduce costs, and meet the growing demands of the market.