In the world of electronics manufacturing and product development, sourcing components efficiently can make or break a project. With increasing global demand, fluctuating supply chains, and technological advancements happening at lightning speed, securing the right parts at the right time becomes a critical step in your workflow. So, how can you stay ahead and ensure smooth and cost-effective component procurement?

Understanding the Sourcing Landscape

Sourcing electronic components isn't as straightforward as picking items off a shelf. It involves navigating a complex network of distributors, manufacturers, brokers, and suppliers. Each source has its pros and cons, and understanding their roles in the supply chain can give you a competitive edge.

Authorized Distributors vs. Independent Brokers

Authorized distributors offer peace of mind when it comes to product authenticity and quality. Their close ties with component manufacturers ensure that the parts are new, genuine, and come with warranties. On the other hand, independent brokers can be lifesavers during shortages, offering access to hard-to-find or obsolete parts. However, they often come with higher risks, including counterfeit components and inflated prices.

Global vs. Local Suppliers

Working with global suppliers can open the door to a wider inventory and competitive pricing, especially in regions known for large-scale production. Local suppliers, however, might offer faster lead times and better communication due to proximity. Balancing both options depending on your project needs can reduce delays and improve efficiency.

Building Strong Supplier Relationships

Long-term success in sourcing electronic components heavily relies on the relationships you cultivate with your suppliers. Trust, transparency, and mutual benefit should be the foundation of your sourcing partnerships.

Communicate Your Forecasts

Suppliers value consistency and predictability. By sharing your production forecasts ahead of time, you give them the ability to plan inventory, allocate stock, and prioritize your orders. This minimizes unexpected delays and strengthens your business relationship.

Evaluate Supplier Performance

Don’t just assume a supplier is meeting expectations—regularly assess their performance on key metrics like delivery time, product quality, responsiveness, and flexibility. These evaluations help you spot red flags early and allow you to make informed decisions on whether to continue or reconsider your sourcing strategy.

Ensuring Component Authenticity and Quality

The rise in counterfeit electronic components presents a serious threat to manufacturers. Poor quality or fake parts can lead to product failures, recalls, and reputational damage, making quality assurance a critical sourcing priority.

Partner with Certified Suppliers

Always prioritize working with ISO-certified and ESD-compliant suppliers. Certifications are indicators of a supplier’s commitment to quality and operational standards, offering you more assurance that the parts you're receiving are genuine and handled properly.

Use Testing Services When Necessary

If you must source from brokers or lesser-known suppliers, don’t skip third-party testing. Services that conduct X-ray inspections, decapsulation, and electrical testing can help verify the authenticity and functionality of your components before they go into production.

Managing Lead Times and Pricing Volatility

Lead times for electronic components can fluctuate wildly based on global demand, supply chain disruptions, and component lifecycle status. Staying agile and proactive is key to managing these uncertainties.

Monitor Market Trends

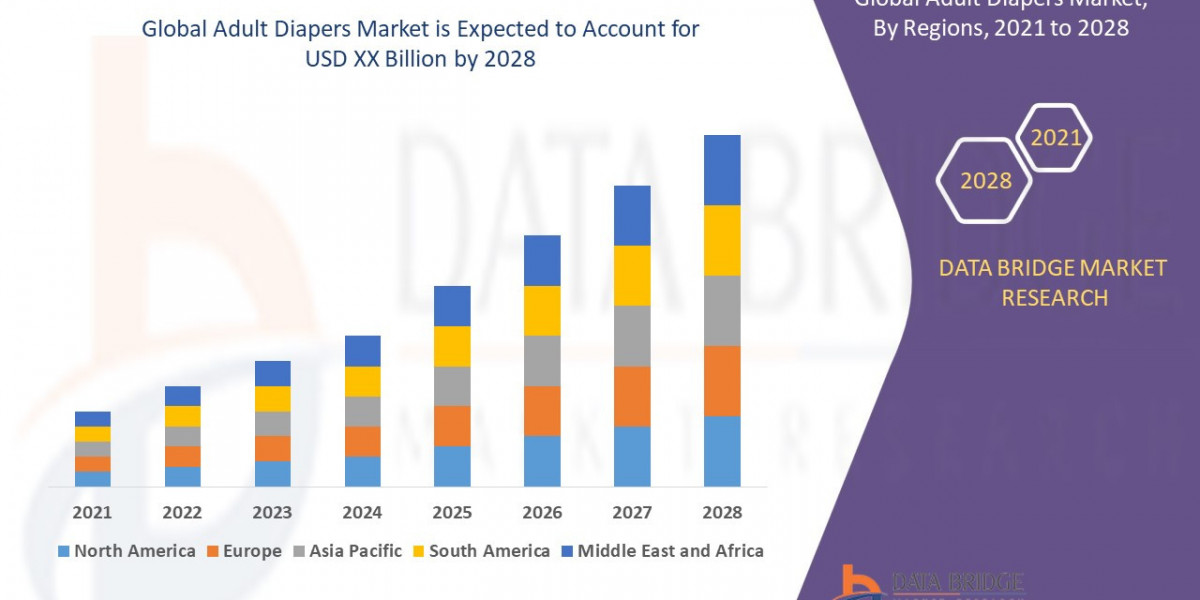

Keep tabs on industry reports and market forecasts. Knowing when certain components are expected to be in high demand—or when factories are likely to close for holidays—can help you stock up in advance and avoid costly delays.

Leverage Volume Purchasing Wisely

Bulk purchasing can secure lower prices and reserve stock, especially for high-use components. However, it ties up capital and can lead to waste if demand forecasts are off. Work with suppliers who offer flexible minimum order quantities or consignment models when possible.

Dealing with Obsolescence and Shortages

Nothing stalls production like an unexpected end-of-life (EOL) notification on a critical part. Planning for obsolescence and responding effectively to shortages is part of a strong sourcing strategy.

Implement Lifecycle Management

Use product lifecycle management tools and databases to track the lifecycle stage of your components. These tools can alert you when a part is approaching EOL, giving you time to redesign or stockpile alternatives.

Design for Flexibility

When designing products, choose components with multiple sourcing options or equivalent alternatives. This reduces dependency on single parts and gives your procurement team flexibility in case of shortages or discontinuations.

Optimizing Your Internal Procurement Process

Beyond external factors, how your team approaches procurement internally plays a big role in sourcing effectiveness. Streamlined workflows and digital tools can reduce errors and speed up decision-making.

Use Procurement Software

Modern procurement platforms can automate RFQs, manage supplier data, track inventory levels, and alert your team to low stock or delays. These systems reduce manual work and improve visibility across departments.

Cross-Functional Collaboration

Sourcing isn't just a job for procurement professionals. Collaborating with design engineers, quality assurance teams, and finance ensures that decisions are aligned across performance, budget, and compliance expectations.

Final Thoughts

Sourcing electronic components is no longer just about finding the lowest price—it's a strategic function that directly impacts your bottom line, product quality, and time to market. By building strong relationships, staying alert to market changes, ensuring authenticity, and streamlining your internal processes, you can turn sourcing into a competitive advantage.