This question delves deep into the heart of industrial evolution, uncovering why fibre laser welding machine have become the preferred choice for manufacturers around the world. From aerospace to electronics, and from automotive to fine jewelry production, the rise of this advanced technology tells a compelling story of progress and possibility.

Understanding the Technology Behind a Fibre Laser Welding Machine

Before exploring its superior performance, it’s essential to understand what sets a fibre laser welding machine apart in its construction and function.

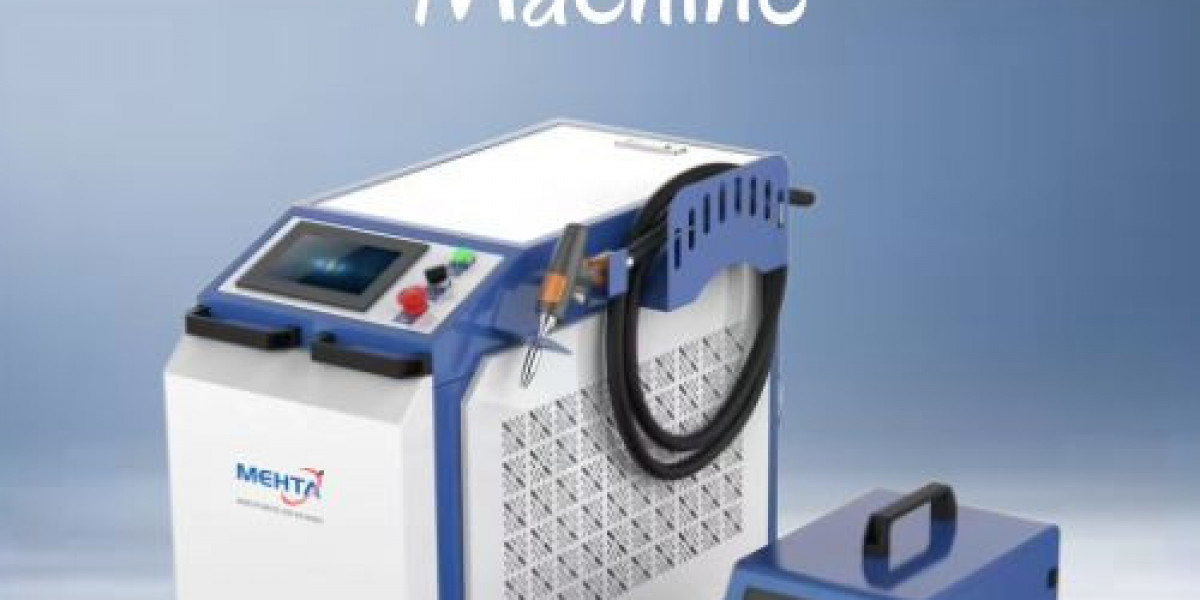

Unlike conventional welding systems that rely on electrical arcs, gases, or filler materials, fibre laser welding utilizes a highly focused beam of light, delivered through a fibre optic cable. This laser beam melts the material at the joint, creating a strong, clean weld. Because of its concentrated energy and precise targeting, it offers control at a microscopic level — a capability beyond the reach of standard arc welding techniques.

The laser source is typically created using a series of diodes, which then pump the light into a flexible fibre optic cable. This setup not only improves efficiency but also increases durability, minimizing maintenance and maximizing uptime — a major factor in commercial production lines.

Why Precision Matters More Than Ever

Modern components — especially in high-stakes sectors like medical device manufacturing, aerospace, and electronics — are becoming increasingly miniaturized. With such tight tolerances, even the slightest error in weld positioning or heat control can lead to product failure, safety concerns, or enormous losses in productivity.

Traditional welding systems often struggle with these demands. They generate excess heat, lack focused energy delivery, and may deform delicate materials. On the contrary, a fibre laser welding machine delivers unmatched accuracy, ensuring that the weld is applied exactly where it's needed — no more, no less.

This level of precision is not just a luxury — it’s a necessity. Whether you’re working on intricate engine components or ultra-fine circuit boards, this technology ensures every joint meets the strictest quality standards.

The Shift in Manufacturing Trends

Across industries, there’s a noticeable shift towards automation, lean production, and smart manufacturing. In this evolving environment, the role of human operators is being redefined, with greater emphasis on programming and monitoring rather than manual labor.

A fibre laser welding machine fits perfectly into this landscape. Many models are fully integrable with CNC (Computer Numerical Control) systems and robotic arms. This not only reduces human error but also speeds up production while ensuring consistent results across thousands of units.

Manufacturers are increasingly prioritizing traceability, reproducibility, and compliance with international standards. These demands require tools that deliver uniform quality, minimal rework, and exceptional control — all hallmarks of a fibre laser welding setup.

Application in High-Demand Industries

1. Automotive Industry

From battery pack assemblies in electric vehicles to lightweight aluminum chassis components, the automotive sector has embraced fibre laser technology. The reason is simple: it allows for the creation of strong, lightweight joints with minimal distortion, a crucial factor for performance and fuel efficiency.

2. Medical Device Fabrication

Surgical tools, implants, and diagnostic devices often require welds that are not only precise but also free from contamination. A fibre laser welding machine delivers clean, sterile joints ideal for instruments that come into direct contact with the human body.

3. Aerospace Engineering

In aerospace, every gram and every micron matters. Fibre laser systems make it possible to join titanium and other specialized alloys without weakening the material or compromising on weight — a challenge traditional welding cannot overcome.

4. Consumer Electronics

Smartphones, laptops, and wearable devices all require fine, strong welds within tight confines. The micro-welding capabilities of fibre laser machines cater to this exact need, allowing for invisible joints and smooth finishes.

Environmental and Energy Efficiency

Another subtle yet significant reason fibre laser welding machines outperform their traditional counterparts is their energy efficiency. The laser’s concentrated energy minimizes waste, and since the heat-affected zone is so small, there’s less thermal distortion and virtually no need for post-processing.

This translates into tangible environmental benefits — reduced power consumption, minimal material waste, and a safer workspace with fewer fumes or toxic byproducts. These aspects are becoming increasingly important as companies strive to meet green manufacturing standards and reduce their carbon footprint.

Maintenance and Operational Longevity

While traditional welding machines often suffer from wear and tear, needing regular replacement of parts like electrodes or gas nozzles, fibre laser systems are designed for long-term reliability. The laser source typically offers tens of thousands of hours of operation with minimal maintenance. Plus, the absence of mechanical contact points in the welding process means fewer opportunities for breakdown.

This makes a fibre laser welding machine not just a high-performance solution but also a cost-effective investment over time. In a competitive market, that matters more than ever.

Seamless Integration into Smart Factories

One of the overlooked strengths of fibre laser technology lies in its compatibility with Industry 4.0 infrastructure. Many machines now come equipped with IoT sensors, cloud-based monitoring, and AI-driven analytics (without the need for the user to understand the underlying AI).

This enables factory operators to monitor performance in real-time, predict maintenance needs, and optimize workflows. The result is a welding station that becomes an active part of the production ecosystem, continuously contributing to efficiency and quality control.

Training and Workforce Development

Although the technology behind a fibre laser welding machine is complex, the user interfaces are designed to be intuitive. With touchscreen displays, real-time diagnostics, and programmable settings, operators can be trained quickly.

This opens doors for a wider range of workers, empowering technicians to manage high-precision welding systems without years of specialized experience. Companies benefit from faster onboarding, improved workforce versatility, and smoother transitions to automated production.

Investment Value and Business Growth

When choosing equipment for long-term use, decision-makers look for tools that not only solve today’s problems but also adapt to tomorrow’s demands. A fibre laser welding machine excels on both fronts.

Its ability to handle diverse materials, support rapid prototyping, and integrate into complex production lines ensures it remains relevant as industries evolve. Whether you're a small fabrication shop or a multinational production facility, this investment can significantly enhance your capacity and output — unlocking new markets and higher revenue potential.

Final Thoughts

As we revisit the tricky question — Why does a fibre laser welding machine outperform traditional welding tools in critical precision tasks? — the answer becomes clear through a combination of technological prowess, application versatility, and future-readiness.

It’s not just a matter of being more modern; it’s about being more capable. The fibre laser welding machine stands as a pillar of precision manufacturing, transforming not only how products are made but also how industries think about quality, speed, and sustainability.

For businesses aiming to stay ahead of the curve, integrate cutting-edge tools, and meet the highest production standards, there is no tool more essential than a fibre laser welding machine. Whether you're in high-tech engineering or specialized metalwork, it's time to weld the future — with light.

Would you like help writing a product description or promotional copy for your fibre laser welding machine business?